The properties of permeable resin bound paving, and the applications it's suitable for - Sureset

Please contact us via contact@construction-cpd.com to get permission to publish this video on your website.

<div style="position: relative!important; width: 100%!important; min-height: 700px; overflow: hidden!important; padding-top: 56.25%!important;"><iframe src="https://www.construction-cpd.com/cpd-external-view?ExternalId=115&ReturnUrl=https://www.construction-cpd.com/the-properties-applications-permeable-resin-bound-paving-cpd" style="position: absolute; top: 0; left: 0; bottom: 0; right: 0; width: 100%; height: 100%; min-height: 500px; border: none;" mozallowfullscreen webkitallowfullscreen allowfullscreen></iframe></div>

Please complete a short questionnaire to gain your cpd points.

Do you notice the surface you walk over? As you can see here the surfaces in situ serve a purpose, but are they memorable?

Resin bound paving creates beautiful, long lasting and environmentally friendly paved surfaces. Suitable for various applications from rural foot paths to town centres, driveways to access roads. There are different types of resin surface available:

Login to record your CPD points

Resin bonded

Resin bonded is a two layered scatter system where the resin is sprayed onto the ground and the aggregate sprinkled on top. This system is prone to loose stone as only one side of the aggregate is attached to the resin surface. The design life for this product is approximately 5 to 8 years.

Resin bound

Resin bound is a one layer system which involves mixing the aggregate and resin together prior to laying. The aggregate and resin is then laid as a mat, one layer. And it's a lot thicker than a resin bonded surface providing a durable, long lasting surface with no loose stone and a design life of around 25 years.

So why use resin bound paving?

- It’s an environmentally friendly surface where each aggregate particle is fully coated in resin to ensure that they all bind together, resulting in no loose stones.

- Voids are left within the surface making it permeable to air and water.

- The surface is smooth for pushchairs, wheelchairs, bikes, skateboards etc.

- Attractive to make regeneration projects stand out.

- Durable and hard wearing for areas with heavy traffic such as town centres and access roads.

- Permeable making it suds compliant.

- It’s great to use around trees with high permeability and low maintenance levels.

It’s important to have a big product range which contains materials varying from natural gravel to marble and recycled glass. The natural aggregate range contains gravels and crushed rock which are mainly buff and tan in colour. You can see here the crushed rocks contain other materials including grey and red granite which look beautiful and natural wherever they are.

Marble Range

The marble range consists of various colours of naturally sourced marble. Some of the lighter colours offer subtle tones which look completely natural and won't fade or turn yellow in the sun due to our UV stable resin.

Spectrum Range

Spectrum is a range of recycled glass which includes primary, glittery, pastel and pearlescent colours. The colours are produced in house using 100% recycled glass. As you can see here the spectrum range consists of very bold bright colours which look fantastic and really brighten up any area. Spectrum colours really shine when they are used to recreate logos, the attention to detail achieved is outstanding and it’s often used in school entrances, recreating badges like manchester city football club here, as well as in the public realm and regeneration projects.

As we produce the colour coated glass in house, bespoke colour blends are offered and known as fusion because its created from a fusion of different colours. Fusion is the ideal option for areas where a specific blend of colours is required to complement or contrast an existing structure or when something from the standard range doesn’quite match. These blends are just examples, any colours of your choice can be fused together.

Resin

Let's now take a closer look at the resin that is used in high quality resin bound system. The resin should be crystal clear, just like water. It’s three-part chemically curing. The resin should be polyurethane not epoxy, this is because polyurethane is more flexible and the properties allow the surface to expand and contract with any freeze thaw action and also coat with a small amount of movement.

The resin is derived from a renewable plant source. It's important that you select a resin bound surface that is UV stable; this will ensure the both aggregate and resin dont yellow over time even when using a white material.

The ideal base for resin bound paving is dense asphalt or a concrete base. This can be an existing surface, however it must be free from cracks and undulations.

This is an ideal base and this base is not.

Any surface like this one must be repaired prior to installation.

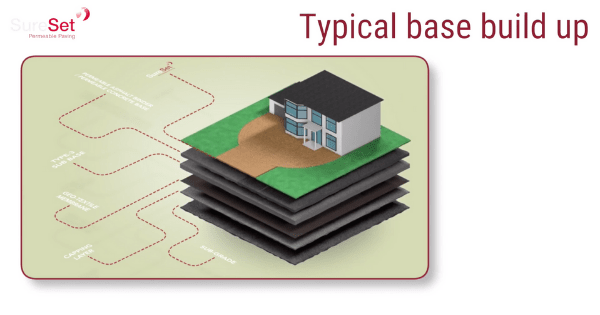

Typical Base Build Up

This is a typical specification advice for pedestrian and vehicular traffic. You’ll need 150 to 225 mm of type 3 sub base followed by a 70mm depth of an open graded asphalt, less than 14mm in aggregate size. The resin bound surface is then placed on top of the asphalt at a depth dependent on the aggregate size and application type. This will give you a fully SUDs compliant base build up.

When installing resin bound onto concrete the base must have been in place at least 7 days prior prior to the installation. The base must be primed with a pu primer prior to application. If there’s expansion joints in the base they must be reflected through to the final surface. As we’ve said resin bound paving can also be used for installation around trees, there are different options for the base of this application. Free draining aggregate is the most popular solution.

Existing soil, cellular structures can be used for heavy traffic. Metal trays can also be used as a base which enables access to the root ball of the tree without disturbing the resin bound paving. Resin bound paving is great for areas where a smooth accessible finish is required. For example on sloping driveways where you want the look of loose gravel but not the problem of migrating stone. It’s ideal for wheelchair access.

Here you can see that the accessible symbols are in situ, nice and white. This was not done using a mastic material. These symbols were inserted using mdf stencils and a white resin bound surfacing. All products are permeable allowing air and water to permeate through the surface, which allows homeowners to use resin bound without the need for planning permission.

DIY kits cover a half a metre squared at a 16mm depth, ideal for small areas or repair work.

Trade packs are designed for experienced tradesmen or builders to install permeable resin bound paving themselves and comes with a sufficient quantity of aggregate and resin to install a minimum of 30 metres squared at a 16mm depth.

Repairs

Repairs can easily be completed using the same blend as the original material. We advise chiseling out the area and infilling with the same material to make an almost seamless repair.

Bespoke Designs

MDF stencils can be used to create design. The stencil is cut to shape, laid on to the ground and gradually areas surrounding the stencil are infilled. Once cured the remainder of the design can be completed.

You can see here with the manchester city badge that these stencils work fantastically well. Depending on the intricacy of the design and the definition required some need permanent metal edging to define the design. Others are butted against each other. Or they can be blended together. This is often in situ prior to our arrival on site, however for less intricate designs we can offer to design and install the edging for you.

It's imperative to ensure that the base is level prior to starting installation of the formwork, to ensure the best possible finish is achieved. A permanent edge is required to surround a resin bound surface and takes several forms: bricks, timber, metal or even drainage channels and existing buildings.

Installation

Installation of a resin bound surface is conducted by achieving levels with a squidgy. Compacting and troweling with a combination of hand and mechanical tool achieving a smooth compact finish. Approximately 250 metres squared can be installed within just one day, any area exceeding this will need a day joint.

This is a seam which will remain visible however if designed into your project it could be avoided by the use of another material such as block paving to break up the area.

There is full control of the curing time when using resin bound. The standard curing time is approximately 6 hours however in the event that you need emergency access and need to get to the area more quickly after laying, this can be altered.

Intricate Design - Blended and Stencil - Resin Bound Paving

Alternatively, if the design is intricate for example and extra working time of the material is required, the curing time can be extended accordingly. Unique design can be achieved for example in this rainbow, bright colours, accurate blending and bespoke materials were needed to create a seamless rainbow. The lines of the rainbow were marked out by hand and the colours were blended into one another. Over 36 bespoke colours were created to represent the colours of the rainbow. Each colour was individually hand floated and then blended into the next creating the incredible rainbow effect on the pathway.

Environmental Aspects

Now you know about the installation of the product let's talk a little more about the environmental aspects of resin bound paving. The laying method is a low energy, cold laid process. The surfacing is a low emission system using only non-volatile components.

The resin used is from a renewable plant derived source. At the end of its useful life, the product can be reused as an inert aggregate. It's always best to try and use a sustainable urban drainage system known as SUDs where possible. Resin bound requires little maintenance, you can simply brush or power wash the surface, at a maximum pressure of 150 Bar. Chewing gum can be removed from the surface using the heating or freezing methods.

Summary

- We are committed to providing the best solution using the best product for the best value.

- Sureset resin bound paving is guaranteed for 21 years against: loose stone, cracking, oil damage, frost damage, UV degradation, colour change and workmanship. Here’s a quick summary of what we have covered.

- Permeable resin bound paving is currently widely specified by local authorities and architects.

- It’s important to clarify the difference between resin bound and resin bonded.

- High quality resin bound paving should consist of a three-part chemically curing resin system providing fully bound material, flexibility, strength, adhesion and UV stability.

- Aggregates should be washed, dried, graded and bagged prior to use. Aggregates are blended specifically for each application ensuring suitability for each traffic type.

- We offer a 21 year guarantee.

Thank you for your time.

Please submit any questions to your team and remember to complete our questionnaire.

Hi - very good, concise CPD. I want to use Sureset on a client's drive. This currently has studded clay pavers. It is stable and suitable for intended loading, but obviously the Sureset will need to be of varying thickness because of the studs. Is this OK.?