Sustainable Timber Doors, Windows and Cladding with a Minimum Service Life of 60 Years - Accsys

Please contact us via contact@construction-cpd.com to get permission to publish this video on your website.

<div style="position: relative!important; width: 100%!important; min-height: 700px; overflow: hidden!important; padding-top: 56.25%!important;"><iframe src="https://www.construction-cpd.com/cpd-external-view?ExternalId=36&ReturnUrl=https://www.construction-cpd.com/sustainable-timber-doors-windows-cladding-cpd" style="position: absolute; top: 0; left: 0; bottom: 0; right: 0; width: 100%; height: 100%; min-height: 500px; border: none;" mozallowfullscreen webkitallowfullscreen allowfullscreen></iframe></div>

Welcome to this online CPD module on the most durable, stable timber for windows, doors, cladding and decking. Accoya is the brand name of a modified wood made by a process called acetylation and will hereafter be referred to as “Acetylated wood”.

Learning Aims

By the end of this course, you will understand:

- What is acetylated wood?

- What are the benefits of acetylated wood?

- What tests have been made on acetylated wood?

- What is the environmental impact of acetylated wood?

- What can acetylated wood be used for?

Login to record your CPD points

Features of Acetylated wood

In this section we will explore the features of Acetylated wood. Modified wood is not the same as treated wood. There is more than one way to modify wood either chemically, physically or by a combination of the two in such a way that improved performance comes directly from the wood and is not dependent on a chemical that may leach out of the wood or degrade over time.

Treatment of wood only results in an envelope of protection. If the wood is cut, carved or damaged, unprotected wood is exposed. Accoya and most other modified woods are modified throughout the board so there is no risk of exposing unprotected wood. Biocide treatment of wood only improves its durability.

Depending on the type of process used, modification results in additional performance improvements such as stability, hardness, coating performance and therefore durability. Treatment of wood is much cheaper than modification. Acetylated wood is sustainably grown softwoods and non durable hardwoods which have been modified through to the core. In general, modification of wood can be regarded as an active modification because it results in a distinct chemical change in the macromolecules of the cell wall.

Acetylation increases the amount of naturally occurring acetyl molecules and reduces the amount of hydroxyls. The revolutionary acetylation process improves the wood’s durability, stability, and coatings service life plus many other characteristics. Acetylated wood is ideal for exterior applications where high performance is required such as windows, doors, siding, decking, outdoor furniture and structural projects such as bridges.

Acetylated wood:

- Has been studied by wood scientists around the world since the 1920s.

- Is the “gold standard” against which other timber treatment and modification methods are benchmarked

- R & D started in 1980’s leading to a commercial product

- Has been commercially available since 2007

- Now sold in more than 60 countries

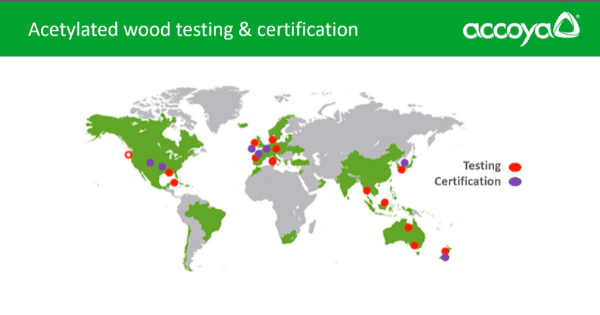

Acetylated wood is produced in Arnhem, the Netherlands. Accsys made an early decision to test the product on a long term basis in the markets it planned to develop. Test sites have been set up around the world. Many of these tests have contributed towards product certifications. Several of the product certifications require independent audit visits from the certification bodies on multiple occasions per year to take random samples from the production floor and analyse for compliance to the certified specification level.

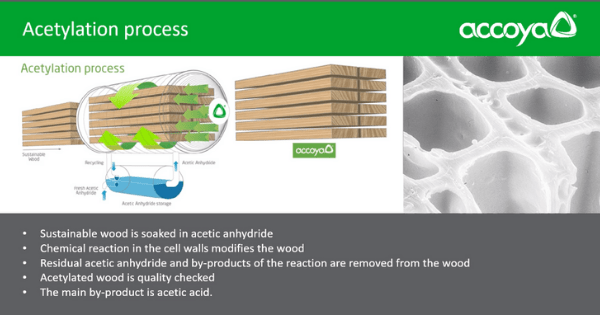

The acetylation process changes the balance of naturally occurring chemicals in wood. An abundance of chemical groups in the wood called “free hydroxyls” absorb and release water, which causes wood to shrink and swell. Acetylation transforms free hydroxyls into larger, stable acetyls to which water cannot bond. As a result water is largely precluded from the cell wall, which makes the wood durable, stable and a barrier to insect decay with many other benefits.

Acetylation makes cellulose resistant to moisture, through a non toxic process it converts problematic hydroxyl molecules to natural acetyl molecules. Increased acetyl molecules improve resistance to the effects of moisture. Wood’s movement, rot and termite problems are due to moisture.

Quality control is paramount and every batch is tested for an adequate degree of acetylation which thereby ensures that class 1 durability and exceptional stability is achieved. Only product that passes these stringent tests is released for sale. This consistent quality enables an industry leading 50 year warranty for rot, decay and stability to be offered giving peace of mind and an assurance of outstanding performance.

Benefits of Acetylated Wood

In this section we will explore the benefits of acetylated wood. Acetylated wood has benefits architects can deploy to improve wood product performance and broaden the scope of wood applications and design. These benefits include decay resistance, dimensional stability and enhanced film coating longevity. A second tier of benefits include surface smoothness and increased hardness. Acetylated wood has been used extensively across the UK, mainly in window projects, with 1000’s of joinery companies having been converted to using Acetylated wood. Acetylated wood has been specified around the world for more than 10 years for prestigious cladding projects which will feature later in this module.

Let's look at these benefits in more detail….

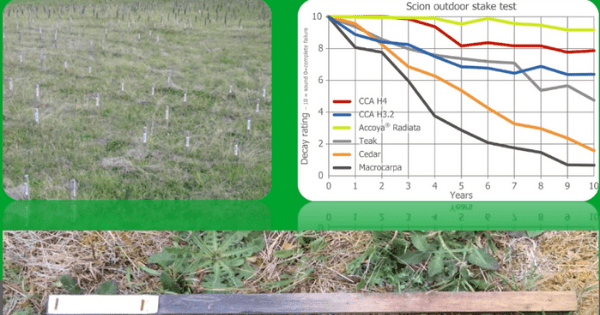

- Durability testing is run for extended periods, to local standards at locations across the world including New Zealand.

- Accoya is tested alongside CCA H4, Teak and western red cedar at the SCION graveyard test field in Rotorua.

- Stakes are inspected on 12 month intervals by the SCION staff and scored on a scale from 10 (perfect) to 0 (totally destroyed).

- At the 10 year point only colour change has been noted for the Acetylated wood samples while all other wood types have either onset of decay or significant decay

The image of the stage above was on removal from the SCION Grave yard trial at 10.5 years.

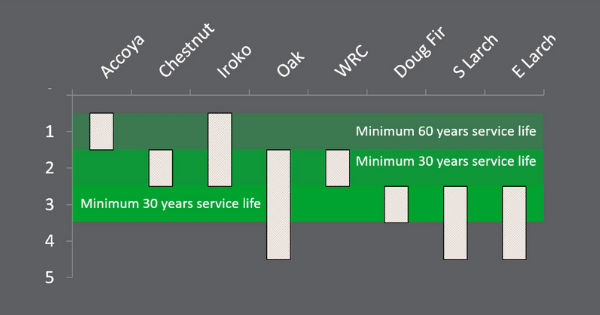

The chart details the durability classes of timber species commonly used for cladding in the UK. The scale runs from 1 to 5 with 1 being the most durable and 5 the least. Timbers of class 4 or 5 are not recommended for external cladding unless treated in some way. in considerable variation in durability that cannot be predicted. Note that the durability class is only applicable to the more durable heartwood of each species so if any sapwood is present then the durability will be significantly less.

Note also that with many species the density of the board has a significant effect on its durability, resulting in considerable variation in durability that cannot be predicted.

BS8417 attributes a minimum service life to products made from timbers of different durability classes according to the use class in which the product is used. Under this standard, external timber cladding made from timber of durability class 3 can be expected to have a minimum service life of at least 15 years, without treatment or modification of the timber. Under BS8417 external cladding made from a timber of durability class 2 such as western red cedar can be expected to have a minimum service life of 30 years.

Under BS8417, the only cladding that can be assured of a minimum service life of 60 years is that made from a class 1 durability timber and the only truly class 1 durability timber commonly used for cladding in the UK is Accoya. With good design and perfect installation and correct selection of timber from the right source it is possible for cladding made from a class 3/4 timber such as Siberian larch to last 30 years or more, but there is a risk that it won’t. Accoya offers peace of mind that a long service life will be achieved regardless.

As the manufacturers of Accoya/Acetylated wood, Accsys Technologies offers a 50 warranty against significant rot or movement on Acetylated wood in applications where it is more than 200mm above ground and 25 years when in contact with the ground and/or freshwater. Because of lack of data on the effects of marine borers on acetylated wood, there is no warranty on acetylated for applications where it is immersed in salt water but there is no problem with using Acetylated wood in situations where is might get splashed with salt water (e.g. marina decking).

Take a look at this swellometer video. This is a trial comparing the acetylated wood and radiata pine. You can see the difference between the dimensional change when immersed in water. Using a small piece of wood of 3 x 6 cm. The number displayed on the dial gauges represents the expansion of the wood in mm. Note that the untreated wood starts to expand immediately and then continues to expand for most of the hour covered by the video. Acetylated wood expands initially but then stops expanding after about 30 minutes. Over the period of an hour the unmodified pine has moved about 10 times more than the acetylated version of the same species.

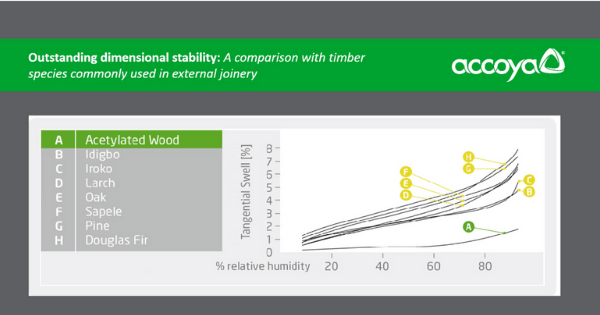

Small pieces of each species were oven dried to remove all moisture and thus reduce them to their minimum sizes. The dimensions of each piece were then measured before the pieces were gradually exposed to increasing humidity, being allowed to acclimatise for two weeks at each humidity step. With increasing humidity the timber pieces absorbed more moisture from the atmosphere and therefore increased in size. The percentage swell has been plotted against the relative humidity in the attached graph, which demonstrates that the movement of Accoya due to changes in humidity is typically at least three times less than that of other species used for external joinery. Such increased stability significantly reduces the risk of windows and doors distorting in conditions of changing humidity and of coatings failure due to movement at joints.

An independent test by TRADA shows that acetylated wood has minimal distortion, even under experimental conditions designed to induce cupping. In these tests it was shown to outperform other timbers commonly used for cladding in the UK. The benefits of such stability are particularly important in applications where design details such as wide boards or open mitre joints push the performance of timber beyond traditionally acceptable limits.

Further testing by TRADA on acetylated wood cladding has given them the confidence to support the use of T&G cladding as thin as 15mm up to widths of 195mm. For unmodified timber their recommendations would be minimum 18mm with a maximum width of 125mm, illustrating that acetylated wood opens up more scope for design with timber. As we’ll see later, the exceptional stability of acetylated also leads to significantly longer maintenance intervals for film-forming coatings.

- Acetylated wood has superior resistance to the effects of UV exposure

- The wood’s natural appearance is retained for longer

- Translucent coatings perform well with acetylated timber provided they are correctly applied

- Acetylated timber will eventually grey like most other timber

Like most other timber, acetylated wood is susceptible to surface moulds that can cause discolouration in situations where the wood doesn’t get the chance to dry out regularly (e.g. shaded or north-facing aspects). These moulds are not rotting the wood but can be aesthetically displeasing. Also, as with other timber, the rate of greying is dependent on the degree of exposure to UV light and may vary across a wall. The only ways to avoid such effects in a cladding situation, as with other timbers, is to either pre-weather the timber (a costly and clumsy process) or to coat it.

Acetylated timber is a more stable substrate than other timbers, so coatings are subject to less stress since they have to move less with the timber. As a result, coating maintenance periods are extended with Acetylated wood. The Teknos joinery range of factory applied coating systems are available with 10 year and 12 year warranties on fully factory finished translucent and opaque coatings respectively. This is at least 2 years longer than warranties that Teknos offer on other timber species. The Teknos warranty is available on exterior joinery manufactured from Acetylated wood and covers embrittlement, flaking or cracking of the coating system as a result of a coating manufacturing fault.

This image shows the same rig after 10 years, highlighting the superior performance of the coating when applied to the Accoya.

The improved insulation properties of acetylated wood result from the fact that it holds less moisture in any given atmospheric conditions than other timbers and is of a relatively low density.

Buildcheck, a BFRC (British Fenestration Rating Council) approved assessment body, has proven that a window’s U Value can be significantly improved merely by changing the frame substrate from traditional hardwood to Acetylated wood.

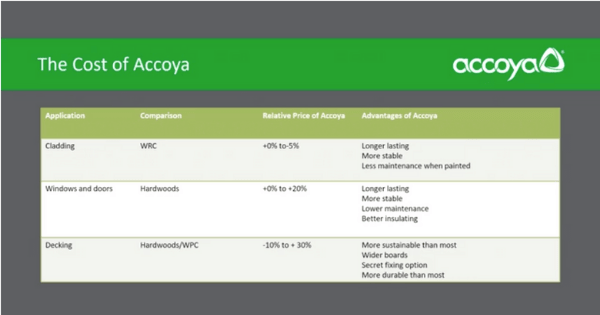

This slide shows data adapted to UK circumstances and currency from data supplied by Dutch maintenance company experienced in working with acetylated wood windows. This company actually offers contracts to customers based on these figures. It clearly demonstrates that although acetylated wood windows may have a higher initial cost, over the long term and the life of the product they can be considerably more cost effective than many other alternatives. Data does not take into account either installation costs or the reduced energy losses from acetylated wood windows. Both factors further support the financial argument for acetylated wood windows when looking at the long term.

Environmental Impact of Acetylated Wood

In this section we will explore the environmental impact of acetylated wood. Acetylated wood is available from legal and sustainable sources including FSC or other regional certified sources. Besides the independent environmental assessments through LCA and carbon footprint, we actively seek to acquire the most respected ecolabels available and have been recognized by others as an exemplary product and company in the field of sustainability on many occasions.

Of the many green building certification schemes available worldwide, BREEAM (mainly used in Europe) and LEED (originating from USA, applied worldwide) are the most widely adopted and recognised. Both are based on various building related environmental indicators including sustainable energy, water and material use. For the latter category the application of Accoya can contribute to several credits in both schemes.

For Europe’s Nordic nations Acetylated wood has been awarded the Svanen Ecolabel. The label, renowned for its rigor and transparency is the internationally recognised ecolabel for Norway, Sweden, Denmark, Iceland and Finland and was established in 1989 by the Nordic Council of Ministers. It was developed to help consumers and companies select products that are guaranteed to have met stringent environmental standards.

Acetylated timber is 100% recyclable and can be disposed of in exactly the same way as unmodified wood. The same applies to any waste material, such as profiling waste. Acetylated timber is 100% non-toxic, protecting the environment from the harmful effects of poisons leaching into the earth. Accoya can be safely incinerated for bioenergy.

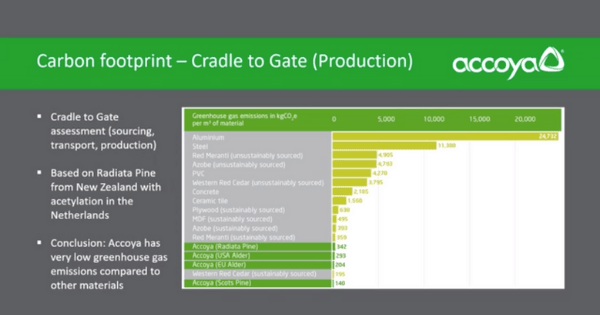

This chart compares various building materials based on production figures (until factory gate, thus cradle to gate) in terms of CO2 equivalent emissions per cubic meters material produced. It clearly shows that Accoya is very competitive in terms of CO2 emissions, this is also caused by the fact that the embodied CO2 of the acetic acid produced during the acetylation process can be deducted from the Accoya CO2 emissions.

Also note the difference between sustainably sourced (i.e. Harvested following sustainably harvesting scheme replanting a new tree for a harvested tree thus keeping the average CO2 stored in the standing volume intact) and unsustainably sourced (clearcut; not replanting a new tree after harvesting) timber in terms of carbon footprint. It should be noted that this chart is not yet fully informative (compares apples with oranges) as it does not included relevant comparison aspects such as:

- Material properties such as density & strength (e.g. Steel I-beam vs Solid wooden beam)

- Durability (life span)

- Maintenance (frequency & materials used)

- Carbon sequestration potential (applies to renewable materials)

- End of life scenario: landfill, incineration or recycling

Therefore the CO2 emissions / m3 material still need to be translated to an application in which the use phase and end of life phase are included, in a so called Cradle to Grave assessment (see next slide)

In every stage of the life cycle Acetylated wood provides compelling environmental advantages, Acetylated wood is produced from FSC timber and FSC certified. An encompassing product assessment has been developed through the Cradle to Cradle assessment. Cradle to Cradle Certification is a rigorous and comprehensive certification program that evaluates products and materials for human health, environmental health and recyclability. Products are analyzed within the confines of five stringent categories; Material Health, Material Reutilization, Renewable Energy Use, Water Stewardship and Social Responsibility. Acetylated wood achieves a Platinum level for material health and Gold in the other four categories.

The Platinum score for material health for a durable wood product is of particular importance as it is often used in sensitive environments and human contact applications. Accoya was one of the first building materials to be classified by the Cradle to Cradle approach in 2010. A number of other products have now been added to the listing from levels of Basic and up.

Acetylated Wood Uses and Case Studies

This section will explore Acetylated wood uses along with some case studies:

- Private house in Guernsey

- Acetylated windows throughout house. Warren Farm in UK.

- Private house in Guernsey

- KFC specifies acetylated wood cladding

- Acetylated wood cladding for private residence in Wirral - As featured on national TV

- Barangaroo R7 Tower, Sydney. KKAA architects (Kengo Kuma).

- Accoya used as boxing, uncoated and intended to grey naturally to match concrete yet soften the façade.

- Barangaroo House, Sydney

- This is the second Louis Vuitton Store in Chile which also used Acetylated wood. There are now 6 stores worldwide that are clad in Acetylated wood.

- In Switzerland again where climates frequently change over the year Acetylated cladding was a good choice by the architects and painted with a grey coating giving it the instant colour they required. The architects chose acetylated wood as the maintenance periods of Acetylated wood are extended.

- Acetylated wood is sold in 50+ countries around the world and are showcased in some stunning projects which can be seen on the subsequent slides. This is a project in Denmark in Europe where Acetylated cladding was used to create a stunning project within the landscape.

- Minnesota State Capitol Building. Accoya replacement windows.

After 10 years exterior use:

- There’s no sign of rot or decay

- Excellent coating performance – No blisters or cracking

- Performs equally on South and North Facades

- An outstanding product, looks as good as new

- Standard timber doors & windows require recoating

Acetylated wood is available from these 6 main distributors. It is also available from an increasing number of other timber/cladding suppliers who don’t purchase directly from Accsys.

In summary

- Acetylated wood is a sustainably sourced, very durable and dimensionally stable modified wood.

- Acetylated wood has a much longer service life and has much lower maintenance requirements than unmodified wood species.

- Acetylated wood has been independently assessed by research institutes across the world, including TRADA, BRE and Napier University in the UK.

- Acetylated wood has a lower environmental impact than many other construction materials.

- The performance benefits of acetylated wood are best realised in exterior applications such as windows, doors, cladding, decking, bridges and outdoor furniture.

Thank you for attending the CPD on Sustainable Timber Doors, Windows and Cladding with a Minimum Service Life of 60 Years.