Providing a Total Façade Solution Part 2 - SPSenvirowall

Please contact us via contact@construction-cpd.com to get permission to publish this video on your website.

<div style="position: relative!important; width: 100%!important; min-height: 700px; overflow: hidden!important; padding-top: 56.25%!important;"><iframe src="https://www.construction-cpd.com/cpd-external-view?ExternalId=116&ReturnUrl=https://www.construction-cpd.com/providing-a-total-facade-solution-part-two-cpd" style="position: absolute; top: 0; left: 0; bottom: 0; right: 0; width: 100%; height: 100%; min-height: 500px; border: none;" mozallowfullscreen webkitallowfullscreen allowfullscreen></iframe></div>

Welcome to this online CPD module on Providing a Total Façade Solution, content supplied by SPSenvirowall.

Learning Aims

Our learning aims for this online CPD module will cover:

- The history of External Wall Insulation – EWI and SPSenvirowall as a solution provider.

- We will explore the legislation that covers the SPSenvirowall range of products and systems; in the main these will be the Building Regulations, Certification, British Standards and European Norms.

- Moving on we will touch on a range of products and measured performances. SPSenvirowall has transformed these products into a range of certificated system solutions.

- Also within this section we will cover the very important subject of innovation. As a market leader in terms of innovation along with certification SPSenvirowall is ready and able to meet future market demands.

Login to record your CPD points

With any building the visual appearance is one of the key factors and within the finishes section we will explore a range of colours & textures along with tips on how to achieve a quality finish.

SPSenvirowall is a leader in Technical Excellence; providing customers with class leading support in the field of Technical expertise. This module will dive through the offer and how SPSenvirowall support their products and systems from the initial design all the way through the specification process and on to the final application. Seeing the finished solutions gives weight to the offering, and so the final section will focus on some completed projects to showcase solutions.

Group Overview Sister Company Relationships

In this section we will explore an overview of the Group.

- Benx Group turn over in excess of £70m and have a diverse range of businesses that supply facades solutions.

- SPSenvirowall – Supply complete render solutions including EWI (Direct Fix or Rail Systems) to masonry backgrounds along with RendaClad solutions for Timber or SFS framing. Finishes include render and brick slips.

- LaRoc – Is a manufacturing arm, developing and delivering render solutions to SPSenvirowall along with private label businesses. They have focus on research and development with an industry leading innovation centre.

- RCM – Provide a range of sheathing boards along with the complete Façade solution from the sheathing board, insulation, helping hands brackets and rail systems to the rainscreen cladding.

Who are SPSenvirowall?

SPSenvirowall:

- Specialise in insulated render and render only systems

- Were founded in 1998

- Employ 60 staff including 10 technical and site support staff

- Have 5 branches nationwide

- Conform to ISO 9001 quality standards, ISO 14001 environment standards & ISO 18001 Health & Safety standards

- Annually SPSenvirowall supply in excess of 1.1 million metres squared of cladding – BrickSlips, Rainscreen, Render and Stone cladding

Systems and Performances

Wall System 1

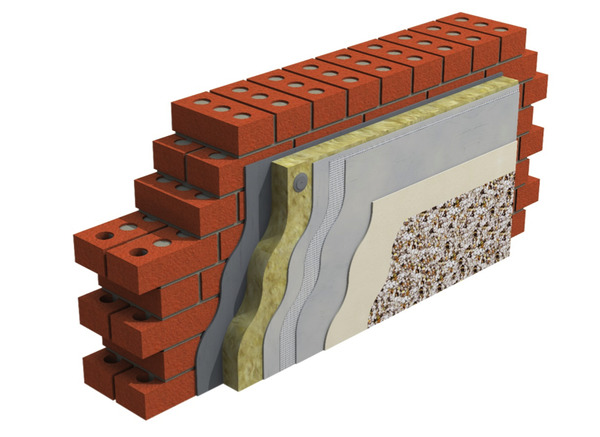

This slide shows Wall System 1 which is for new build projects only.

The system uses mineral wool, Expanded Polystyrene (EPS) and Phenolic insulation

EPS and Phenolic systems achieve Euroclass B-s1, d0 which means and Mineral Wool systems achieve Euroclass A2-s1, d0

This system can be applied directly to both masonry and framed structures and has up to 60 years certified life expectancy.

Wall System 1 is third party certified for masonry constructions only

Wall System 2

Wall System 2, as shown here, is for refurbishment projects only.

This system also uses mineral wool, EPS and Phenolic insulation and can be directly applied to masonry structures.

With up to 60 year life expectancy, the system is third party certified specifically for masonry constructions using EPS insulation.

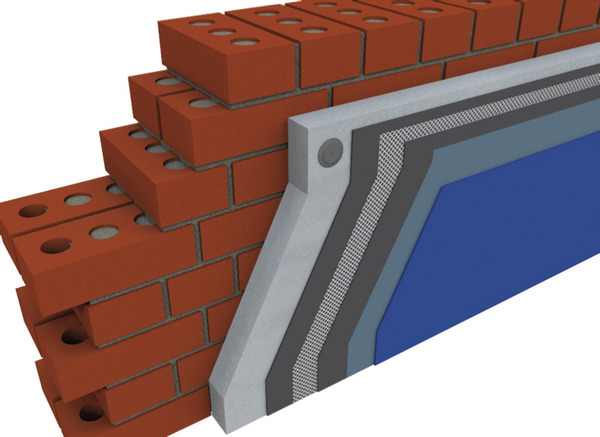

TS Rail system

The TS Rail system as shown, is for use on framed structures such as SFS and timber in order to create a cavity between the insulation and sheathing board.

This system Mineral Wool and EPS insulation can be used on New Build and Refurbishment projects.

As stated previously, EPS systems achieve Euroclass B-s1, d0 and Mineral Wool systems achieve Euroclass A2-s1, d0

The system has in excess of 30 years life expectancy and is Third Party Certified for framed constructions and also certified for use on Park Homes.

Cavity Systems 1 and 2

Cavity Systems 1 and 2 have been developed due to the increase of Mineral Wool insulation used on framed structures such as SFS.

These systems using Mineral Wool and EPS insulation, for use on framed structures only, create a cavity between the insulation and the sheathing board.

These particular systems are third party certified for framed constructions only using Mineral Wool insulation.

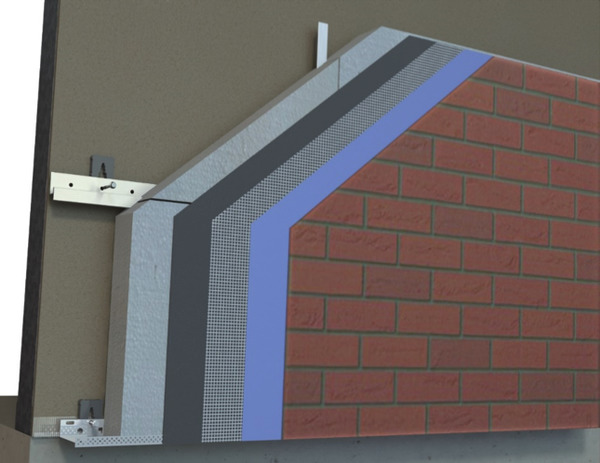

RendaClad System

The RendaClad system is a rendered Rainscreen system used on timber framed structures and can be applied on or off site.

This system does not incorporate insulation and offers a fast track approach to building compared to traditional methods.

This rendered Rainscreen system can be fitted to Light Steel Frames (LSF), timber frames & SIPP structures.

The system is Buildoffsite Property Assurance Scheme (BOPAS) registered, Lloyds Register registered and is third party certified.

Legislative Documents - England and Wales

There are several legislative documents that apply to External Thermal Insulated Composite Systems.

Approved Document A – Structures.

The systems have to be able to support their own self-weight.

The systems must be able to withstand the wind load action applied to the cladding taking into consideration fixing pull out, fixing pull through and bond strength of the render coats. The structure must also be able to support the systems being applied.

Approved Document B – Fire Safety.

Depending on the building height and its location to the site boundary, the Reaction to Fire classification changes.

The systems that SPSenvirowall offer have a Euroclass of B for EPS and Phenolic systems or A2 for Mineral Wool systems.

Should the building have a storey height above 18m, then the insulation must be of Limited combustibility. The system must be compliant with BR 135, which involves using full-scale test data from BS 8414 part 1 or BS 8414 part 2.

On new build residential structure installations on an SFS structure, a cavity may be present behind the insulation that would require compartmentation.

Approved Document C

Site preparation and resistance to contaminates and moisture. The system must resist the passage of moisture from the outside. This is demonstrated by Hygrothermal testing to ETAG 004.

The system must also allow the structure to breathe to prevent excessive build-up of moisture through condensation.

Approved Document F - Ventilation

This only really applies to refurbishment schemes where ventilation levels are high through gaps within the existing structure and around windows. The application of these systems will seal these gaps and decrease the levels of ventilation; therefore ventilation points may be required to achieve compliance.

Approved Document L – Conservation of Fuel and Power.

The system must be able to withstand the passage of heat and achieve the project design U-values.

Non - Legislative documents.

Shown here is a list of non-legislative documents that as a system supplier we (SPSenvirowall) have to comply to or acknowledge and make our customer base aware of.

BR 135

BR 135 is not a direct legislative document; however it is referenced in Approved Document B, Technical Handbook 2 for buildings with a storey height greater than 18 metres. This document, whilst clearly stating within its contents as being for guidance only, has become the go to document for fire with these systems. BR 135 also covers the design guidance for fire barriers that are used and specified within the systems. Testing to BS 8414 may be required for systems using combustible insulation, or assessments based on test data.

MOAT 22

This is the original test model for EWI systems and is still commonly referred to. Some of the original tests are still used today such as wet freeze testing.

ETAG 004

This replaced the MOAT 22 document and is still to be considered the go-to document post Brexit.

This guideline document sets out the test requirements for an EWI system to be awarded with European Technical Approval (ETA).

BS EN ISO 10456 and 13788 (hygrothermal properties referring to the movement of heat and moisture through buildings).

These are the biggest tests that SPSenvirowall’s systems have to comply with. Tests simulate at least 25 years life expectancy for the system and monitors it for water ingress.

Design and Service

Each of the following areas of service will assist in moving your project forward positively:

- AutoCAD Drawings – We have a set of standard details for Fire breaks, Windows, Doors, Soffit line, Parapet Roofline, DPC levels, Movement joints and interfaces.

- We are able to assist in adapting our systems onto a bespoke project detail.

- Bespoke U-value calculations can be created for your project.

- Bespoke condensation risk calculations can be created for each of your projects.

- Bespoke Wind Load Calculations can be provided including location, height, orientation etc.

- Our technical team can create Project Packs that are project-titled e-zipped folders with all project documents. This enables you to control project documents and supports correspondence.

- We also provide access to Technical Data Sheets & Control of Substances Hazardous to Health (COSHH) Data Sheets covering all products, per project.

- e-Folders for our system can be issued as an Operation and Maintenance Manual in support of your main project O&M.

- We are able to conduct pre-scheduled site inspections. These regular technical site-visits help to support the correct application of systems.

- Training programmes – Our training programmes provide application experience for our existing and new contractor base. They can be tailored to suit the requirements of individuals or specific system applications. Those satisfying the course requirements will receive a “Credit card” type approved-contractor card complete with photo and company details.

- Samples of finishes – We provide project specific samples demonstrating colours and textures, enabling an informed decision.

- We are able to provide CGI Images (via Adobe Photoshop) of Render finishes and Brick Slip finishes. Systems are transposed on a digital image enhancing/updating it with new finishes and colours to assist with planning applications and client colour choices.

- SPSenvirowall’s technical excellence comes from its people, innovation and risk management.

Case Studies

Langley Academy Primary School

A modern 2 storey new development designed to house 630 nursery, reception and junior pupils in Slough Berkshire. The new school encompasses a series of rectangular blocks. The objective of the scheme was to deliver the project with minimal disruption to the existing school and its pupils during term time. The new development uses a simple palette of materials consisting of timber cladding, aluminium cladding, render and coloured-spandrel panels. The main teaching block comprises a natural render with simple punch windows. The rear block is a combination of render and timber cladding. The South facade closest to the existing academy is a combination of timber and a smooth finish render.

Working collaboratively, this saw the installation of 1,100 meters of 200mm insulation, which met the desired thermal performance of the building as well as contributing to the fire and acoustic requirements. A silicone topcoat was applied to provide the smooth rendered finish requested by the client. The project plan consisted of a dedicated stock held at a local SPSenvirowall branch to guarantee next day delivery, as well as a delivery schedule to ensure materials were delivered on time to allow deadlines to be met with minimal disruption to the school and the project itself.

The Sedgewick and Barwick

The Sedgewick and Barwick high rise building in Bristol is council owned and was in need of improvements to prevent damp, cold and condensation. As part of the Bristol Homes Standard, Bristol City Council has been working to provide warm, safe and energy efficient homes for its tenants via its Warmer Homes project. The Warmer Homes Project is a 9 year programme to fit external wall insulation (EWI) to 30 blocks of flats and 3,200 homes across Bristol. Sedgewick and Barwick consists of 3 high rise buildings each ranging from 10 – 11 storeys in height consisting of 126 flats, all requiring a thermally efficient insulation and cladding system to reduce heating costs, improve appearance and reduce energy use.

Working with Mears Group and EWI installer Rateavon, SPSenvirowall was required to design and supply the external wall insulation system and ensure a thermally efficient system for the three high rise buildings and reduce running costs for residents. In addition, it was required to improve the appearance in the local area.

The Mural, designed by GCP Architects, on the west elevation of each building now sports a Summer motif using acrylic brick slips to display a green leaved tree and an Autumn motif which displays a brown and yellow leaved tree.

To minimise heat loss, over 4,000m2 of SPSenvirowall grey EPS with an Envirorend base coat, mechanical fixing, high performance reinforcing mesh and acrylic brick slips was installed as part of the external wall build-up. Specified in a thickness of 120mm and 50mm to achieve the target U-value of 0.24 Watts per meter-Kelvin, as required by Bristol City Council standard regulations.

Suitable for high rise buildings, SPSenvirowall’s Wall System 2 can be used for both new and refurbishment projects. To improve the appearance of the building, the SPSenvirowall Clinker acrylic brick slips were used at ground level up to the first floor. A mix of blue, grey and black granomin render was used on the elevations above, updating the look of the building with a new modern façade.

Premier Inn Finzels Reach

The new Premier Inn is a 168 bedroomed hotel and part of the 4.7 acre, mixed-use Finzels Reach development in the heart of Bristol. The client desired a traditional brick façade with a columned appearance, typical of all modern high-rise Premier Inn Hotels, whilst being aesthetically sympathetic to its local surroundings where several grade II listed buildings reside, blending historic buildings with contemporary architecture. To achieve a traditional brick façade would have been costly and time consuming. With this in mind, SPSenvirowall specified its Wall System 1, a solution that utilised insulation with a flexible brick finish to provide the client with the desired look.

Installers Build-Therm Services were able to use over 2000m2 of SPSenvirowall white eps insulation ranging from 150mm to 300mm that assisted in the construction of the stepped appearance on the build whilst using the SPSenvirowall Staffordshire blue and red flexible brick slips to provide the traditional brick façade. The use of SPSenvirowall’s Wall System 1 and flexible brick slips allowed the development to be delivered on time and to budget. The system is lightweight and well suited to the steel frame building while saving time on deliveries and requiring less physical space in which to store the building materials that would have been problematic with a traditional brick.

Junction 3

The Junction 3 development is comprised of 59 affordable homes (incorporating sustainable, energy-saving materials), a Creative Learning Zone, library, crèche, community meeting rooms and seven retail units. The homes were built to Code for Sustainable Homes Level 3, while the other elements of the project all achieved a BREEAM 'Very Good' rating. This unique design and striking aesthetical appearance was coordinated with the client and GCP Architects located in Bristol and has become a focal building at the end of the M32, leading into Bristol City Centre. With such a variance of substrate changes this scheme made use of a variety of SPSenvirowall BBA approved render solutions and finishes. The project required the technical abilities of the design team from all companies to interface these abutment details.

Feature curve walls, waving bulkheads and interchanging colours between the renders were installed onto varying substrates such as timber frame, shear concrete walls, blockwork and secondary steel frame utilising the SPSenvirowall T S Rail, Rendaclad, Insulated render to sheathing board and render only systems. This was a significant test for contractor Woodman Brothers who delivered a high-quality finish. The £460,000 facade package utilised a high performing silicone render topcoat with bold statement colours and the use of the innovated acrylic brick slip system.

Learning Aims

This concludes the online CPD module and in summary you will now have:

- An overview of the SPSenvirowall business, products, systems and service

- An understanding of EWI Products, Systems and Application

- An understanding of the application of Building Regulations & Norms

- An awareness of available finishes and Innovation

- An appreciation of various systems & performances

- Access to discuss design & services