Providing a Total Façade Solution Part 1 - SPSenvirowall

Please contact us via contact@construction-cpd.com to get permission to publish this video on your website.

<div style="position: relative!important; width: 100%!important; min-height: 700px; overflow: hidden!important; padding-top: 56.25%!important;"><iframe src="https://www.construction-cpd.com/cpd-external-view?ExternalId=118&ReturnUrl=https://www.construction-cpd.com/providing-a-total-facade-solution-part-one-cpd" style="position: absolute; top: 0; left: 0; bottom: 0; right: 0; width: 100%; height: 100%; min-height: 500px; border: none;" mozallowfullscreen webkitallowfullscreen allowfullscreen></iframe></div>

Welcome to this online CPD module on Providing a Total Façade Solution, content supplied by SPSenvirowall.

Learning Aims

Our learning aims for this online CPD module will cover:

- The history of External Wall Insulation – EWI and SPSenvirowall as a solution provider.

- We will explore the legislation that covers the SPSenvirowall range of products and systems; in the main these will be the Building Regulations, Certification, British Standards and European Norms.

- Moving on we will touch on a range of products and measured performances. SPSenvirowall has transformed these products into a range of certificated system solutions.

- Also within this section we will cover the very important subject of innovation. As a market leader in terms of innovation along with certification SPSenvirowall is ready and able to meet future market demands.

Login to record your CPD points

With any building the visual appearance is one of the key factors and within the finishes section we will explore a range of colours & textures along with tips on how to achieve a quality finish.

Group Overview Sister Company Relationships

SPSenvirowall is a leader in Technical Excellence; providing customers with class leading support in the field of Technical expertise. This module will dive through the offer and how SPSenvirowall support their products and systems from the initial design all the way through the specification process and on to the final application. Seeing the finished solutions gives weight to the offering, and so the final section will focus on some completed projects to showcase solutions.

In this section we will explore an overview of the Group.

- Benx Group turn over in excess of £70m and have a diverse range of businesses that supply facades solutions.

- SPSenvirowall – Supply complete render solutions including EWI (Direct Fix or Rail Systems) to masonry backgrounds along with RendaClad solutions for Timber or SFS framing. Finishes include render and brick slips.

- LaRoc – Is a manufacturing arm, developing and delivering render solutions to SPSenvirowall along with private label businesses. They have focus on research and development with an industry leading innovation centre.

- RCM – Provide a range of sheathing boards along with the complete Façade solution from the sheathing board, insulation, helping hands brackets and rail systems to the rainscreen cladding.

Who are SPSenvirowall?

SPSenvirowall:

- Specialise in insulated render and render only systems

- Were founded in 1998

- Employ 60 staff including 10 technical and site support staff

- Have 5 branches nationwide

- Conform to ISO 9001 quality standards, ISO 14001 environment standards & ISO 18001 Health & Safety standards

- Annually SPSenvirowall supply in excess of 1.1 million metres squared of cladding – BrickSlips, Rainscreen, Render and Stone cladding

Introduction to ETICS (External Thermal Insulation Composite Systems)

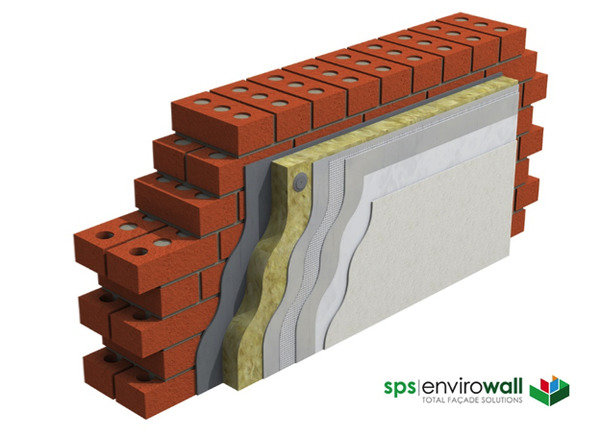

Construction across Europe has many differing styles that have developed over many years. Germany established the early development of External Wall Insulation (EWI) as early as the 1940’s, building from block only wall construction they developed methods of insulating the building envelope externally as this is widely considered to be the optimum position for insulation (on the outside of the building fabric). The UK construction industry has a trusted method of building solid masonry and then cavity walls and saw the introduction of EWI into the UK in the 1960’s.

With the shortage of bricks and bricklayer trades, in conjunction with developers’ demands to deliver a more timely construction method to cater for the increased need for apartments, the UK turned their focus to lightweight steel frame construction. These requirements were a trigger for system manufacturers to further-develop EWI systems to include a drained cavity (Cavity System) and direct fixed-to sheathing boards, in order to support the drive in the housing market. This process of design was quickly adopted by education, health and commercial building projects and so the new build sector experienced a rapid rise in specified EWI applications.

When a Design Concept creates a History of its Own

The construction market is generally slow to react to new concepts and designs. As the history of EWI System development has advanced, it finds itself in an enviable position of being suitable for most façade/construction solutions. The strength of design over its history and highly regulated fire testing regimes has made EWI a system that specifiers return to regularly as it provides a track record of being extensively FULL SCALE fire tested, BBA certified, KIWA certified and recognised by NHBC & other insurers.

As a System Holder we (SPSenvirowall) are responsible for Designing, Providing and Technically supporting “Multi-Component” systems that are tested for Fire and Weather performances such as rain and wind to the highest possible level in the market. This involves world renown testing facilities such as the BBA/BRE/KIWA BDA and Exova Fire Warrington.

EWI has multiple aesthetic cost effective ranges that other systems have not maintained over the years. Façade finishes and systems have come and gone but EWI continues its journey with the specifier and developer. INCA & the NIA are the industry bodies that represent EWI contractors and system holders as a “United front” to Government (and other Stakeholders) where “One voice” is required.

When a Design Concept is All Encompassing

As the insulation is on the external surface, the dew point moves toward the outside of the structure, greatly reducing the risk of interstitial condensation. External wall insulation systems are applied around openings in the external building envelope, eliminating the thermal bridge.

Example substrates are:

- Masonry – Blockwork and existing solid brick substrates – No Fines

- Lightweight steel frames SFS/LSF

- CLT – Cross Laminated Timber

- Timber Frame

- Concrete frames with SFS infill

- Concrete panelled structures

- SIPS

Suitabe for building types including:

- High Rise Apartments above 18m

- Low Rise Apartments/Flats

- Commercial Properties

- Health

- Education

- Park Homes

Insulation - What is it and how does it work?

In this section we will look into more detail on what insulation is, what the types are and the key characteristics of each main type. Heat flow will always occur. It is an inevitable consequence when two objects of different temperatures are in contact with each other.

‘Thermal Insulation’ is the term used for reducing this heat transfer between two objects. Insulation provides a region or zone where thermal energy loss is reduced and allows the heat transfer to be managed. Imagine a Thermos flask, it keeps the heat in, but it can also keep the heat out in warmer months to help maintain the right comfort factor.

How do we measure the thermal performance of building products?

Each product has an insulation value, irrespective of how poor this may be. The most common method of displaying this performance is by declaring the products ‘Thermal Conductivity’. This is known as the Lambda value or the ‘k’ value). The lower this value is, the better the product is. Another method of displaying this is by declaring the product’s ‘Thermal Resistance’. This is known as the ‘R’ value and is more commonly used in Europe. A product’s ‘Thermal Conductivity’ and ‘Thermal Resistance’ are linked; Thermal conductivity is irrespective of product thickness whereas thermal resistance is thickness dependant.

Insulation - Different Types

In this section we will explore the different types of insulation products.Insulation products are split into 3 product types:

Thermoplastic

- Thermoplastic insulation products include Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS).

Thermoset

- Thermoset insulation products include Polyurethane (otherwise known as PUR), Polyisocyanurate (otherwise known as PIR) and Phenolic.

Inorganic

- Inorganic insulation products include Mineral Wool/Stone Wool and Foamglass.

There is one dominant type from each category used in External Wall Insulating Render Systems, EPS, Phenolic and Mineral Wool.

Expanded Polystyrene (EPS)

Selection of an insulation product requires appreciation of the building design requirements and any restrictions imposed. Manufacturers are key sources for product testing data.

The next few slides will highlight the key attributes for each main insulation type with an overview table at the end.

In this section we talk about fire classifications of the insulation products, but these are for comparative purposes only. When considering the use of an ETICS system, it must be remembered that the fire performance declared is for the complete system. Expanded Polystyrene (EPS) used in the External Insulation market is FRA (Fire Retardent) grade, but it still carries a Reaction to Fire classification of Euroclass E. Fire breaks are required at every party floor line, but check with the fire strategy plan for party wall lines. FRA grade EPS requires the insulation to shrink away from the ignition source and also self-extinguish The Lambda value of EPS is 0.038 W/m2K, but this can be enhanced to 0.032 W/m2K. Both products are widely available in the market with very little difference in price. The density of EPS is 15 Kilograms per cubic metre which makes EPS a really light product to add to the structure and also handle on site. It can be easily cut and if needed, a hot wire can also be used to speed up the process or to create features such as ashlar lines. EPS is a high impact and compressive strength solution. It has excellent bond strength making it the operative's choice of insulation.

Phenolic

Phenolic carries a Reaction to Fire classification of Euroclass B making it hard to ignite. Fire breaks are required at every party floor line, but check with the fire strategy plan for party wall lines. The Lambda value of Phenolic varies with thickness and is between 0.020 and 0.023. The most common thicknesses, greater than 45mm, all have a lambda value of 0.020. The density of Phenolic is 40 Kilograms per cubic metre which makes Phenolic a light product to add to the structure and also handle on site. Phenolic is a high impact and compressive strength solution. It has good bond strength, but care is required to ensure the tissue facing is not removed with the trowel.

Stone Wool / Mineral Wool (MW)

The term Mineral Wool (MW) is used extensively but it must be noted that the only Mineral Wool insulation used in this market is Stone Wool. Glass Wool and Ceramic fibres are not used. Mineral Wool carries a Reaction to Fire classification of A1 making it the only Non-Combustible insulation in this market sector. For this reason, separate fire barriers are not required, however consideration for intumescent strips and fire barrier fixings may still be required at party floor and party wall lines. Please refer to the building fire strategy plan. There are no restrictions in its use in terms of the height of the building or its location to a boundary wall line. The Lambda value of Mineral Wool is 0.036 to 0.038, dependant on the grade being used.

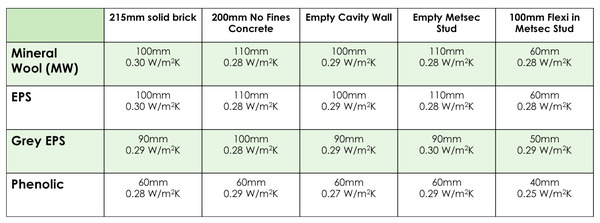

Insulation - Thermal Performance, to achieve 0.30 W/m2K

As you can see from this table, the thickness of insulation needed varies depending on the type and structure.

Insuation Types and Properties

This table presents a brief overview of the key characteristics as taken from the industry trade body INCA Ltd. As shown in the key, three ticks equates to being excellent for the given property.

Product and Performance - Adhesive, fixings and Reinforcement Mesh

In this section we will talk about insulation adhesive, fixings and also the requirements of a reinforcement mesh.

Insulation adhesive

Whilst adhesive is not required as part of the specification and the fact that all of SPSenvirowall’s Certified systems do not demand an adhesive product, insulation adhesive does offer some benefits that you may wish to consider. Insulation adhesive can help to overcome variations in the structural line, but when doing so, care should be taken to ensure the correct fixing length is used.Whilst not considered as part of the system analysis for wind load performance, it does offer an additional securement point and an additional safety factor. The debate over thermal bypass in cavities still goes on and whilst there is no evidence to suggest this happens behind these systems with no adhesive, it is sometimes specified to reduce this perceived risk

Fixings

Fixings form the principle anchoring point to the structure so it is key to get this item correct and ensure the specification matches the design requirements. There are various types available in the market and the substrate will typically determine which one is used. There are screw fixings for calcium silicate or cement based sheathing boards, interset fixings for Magnesium Oxide or Gypsum based boards and expansion anchors for masonry. In each category there are several options and manufacturers such as SPSenvirowall are able to help identify the correct anchor and ensure that as the building design develops, the anchor specification remains true to the structure.

When considering which fixing to use, there are several factors that system designers, need to consider for wind load actions. The key areas are anchor pull out and anchor pull through. Most people are aware of the anchor pull out, but anchor pull through is new to others. This is the ability of the insulation product to remain in place without being pulled over the fixing head. One way to improve this is to increase the size of the washer, another is to fix through reinforcement mesh.

Reinforcement Mesh

The reinforcement mesh layer plays a key part to the systems ability to withstand stresses being applied through building movement, settlement and also thermal gains when using strong darker colours. Reinforcement mesh is a glass woven mesh in grid format of 4 x 4 milimetres. It is coated with polypropylene and has a minimum area weight of 160 grams per square metre. Reinforcement mesh is alkali resistant so will not break down when embedded in the cementitious base coats. Stress patches are required at key locations such as around corners of openings or any penetrations through the system.

It is at design stage that the use of the building and any requirements for additional reinforcement at key locations should be considered. Impact resistance can be improved by the inclusion of a high impact mesh or even the use of a render carrier board. Note that render carrier board requires the insulation to be thinner when being specified.

SPSenvirowall Textured Finishes

SPSenvirowall offer a range of textured finishes in an extensive colour range. SPSenvirowall’s pre-mixed renders can be colour matched to most RAL & NCS colours. If required, non-standard colours are also available. Grain size ranges from 0.5 milimetres to 4 milimetres and can be applied using a trowel or spray applied.

There are a number of synthetic finish types:

- An acrylic topcoat with quartz grain is a weather resistant finish and has the ability to be manufactured in deeper colour palettes.

- A silicone topcoat with quartz grain is a weather resistant finish with a high level of water repellency, reducing opportunity for dirt to cling to the surface and maintaining its asthetic appeal. Silicone topcoat with quartz grain is ideal for coastal locations.

- FlexiSil with quartz grain is a weather resistant hybrid topcoat offering qualities of both the silicone and acrylic topcoats.

Mineral finish types

Once mixed, mineral finishes are applied in the same way as the pre-mixed tub products. Curing of mineral finishes is not reliant on humidity levels. With a 1.5mm grain size, Enviromin is manufactured with NO lime content to avoid unsightly lime bloom (also known technically as efflorescence).

SPSenvirowall - 'Brick' Finishes

SPSenvirowall offer a range of brick finishes that can be tailored to suit the project design.

Speedyslip Flexible Brick Slips

Are lightweight Flexible brick slips ideal for High Rise applications. A standard colour range is available along with an additional “Brick matching” service. This product is approximately 4 milimetres thick and can easily be fixed to basecoat renders with a high flexible bonding adhesive.

SPSenvirowall manufacture standard colours that resemble traditional mortar colours. This product gives the external appearance of a “Real” 3 dimensional brick envelope.

Brickstick - Clay Brick Slips

Are either cut from full stock bricks or manufactured as slips. A standard colour range is available, also with an additional “Brick matching” service.

Envirobrick

A two layered brick or stone effect render that is cut out into patterns. A topcoat colour is applied to resemble the appropriate finish effect. For example herringbone, stone blocks or traditional brick bonds.

SPSenvirowall Traditional Finishes.

SPSenvirowall also offer a range of traditional finishes. Predominantly used on blockwork as a “single” layer render. This product is a powder (supplied bagged) and is mixed with clean water to provide a traditional finish.

EnviroDash

A combination finish of render receiver with Spar aggregate added into its surface. Traditional Spar Dash finishes can be found on houses across the UK with “Hotspots” in Scotland and Wales. A range of traditional colours are available pre-mixed with complimentary coloured backing render receivers. Receivers are generally quartz spar in creams, red & white or black & white.

Granicem L

A single-coat mineral render that provides a Monocouche (scratched render) effect on blockwork.

Summary

This concludes the online CPD module and in summary you will now have:

- An overview of the SPSenvirowall business, products, systems and service

- An understanding of EWI Products, Systems and Application

- An understanding of the application of Building Regulations & Norms

- An awareness of available finishes and Innovation

- An appreciation of various systems & performances

- Access to discuss design & services